Products by Parallel Minds

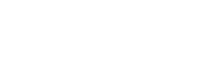

ePower Planner

ePower Planner a SaaS is an Optimal Production Planning Solution empowering manufacturing process. It helps seamlessly align customer demand with production plans, optimizing asset utilization and material requirements. Using ePower planner you can craft own planning calendar and swiftly adapt to changing demands. You can elevate efficiency through online production performance insights, ensuring rapid response to issues. It is ideal for diverse manufacturers – from precision machining to chemical batch processing. It revolutionize your manufacturing strategy.

- Modules

- Features

- Who can use this

Demand Management

- Sales Orders/Project

- Monthly Production Plan

Production Planning

- Generate ASAP Plan

- Generate JIT Plan

- Move Size considerations

- Setup Constraints

- Batch size considerations

- FG Accounting

- WIP Accounting

Maintenance Management

- Breakdown mitigation

- Preventive Maintenance Plan

Capacity Balancing

- Balancing Demand and Capacity

- Provides insights over possible capacity bottlenecks

- Create What-if scenarios of Demand and Capacity mapped over a timeframe.

Production Execution

- Planned Vs Actual Production

- Rejection Analysis and Down time capturing

- Machine Breakdown Impact

Insights

- Machine Loading plan

- Setup schedule

- Raw Material Requirement schedule

- Finished Goods Availability Schedule

- Planned Vs Actual Utilization

- Material Requirement

- Breakdown Analysis

- MTBF / MTTR / Failure Frequency

- OEE

Planning Engines

-

As Soon As Possible

-

As Late As Possible (JIT)

Planning Mode

-

Automatic

-

Manual

Material Movement

-

Continuous Flow

-

Shift to Shift Flow

Demand Generation Thru

-

Monthly/Weekly Plan

-

Fixed Quantity-Duration Sales Orders

Any manufacturer doing

- Metal work (Machined Parts)

- Casting or Molding,

- Sheetmetal work and Fabrication

- Plastic molded parts

- Chemical products (Continuous batch process)

Typical Industries include (but not limited to)

- Enterprises with Machine shops manufacturing various items as per client order

- Enterprises with Press shop manufacturing multiple items from the set of the presses

- Chemical units producing multiple items in a batches