Value Stream Mapping – Current and Future States

Table of Contents

Enter Value Stream Mapping

In the tech world, where complexities are often overwhelming and process traps are prevalent, it is indeed difficult to circumvent bottlenecks and rabbit holes. Still, there surely has to be a solution to it. If these problems are so commonplace, how do some teams deliver agile development solutions and seem to get them right all the time?

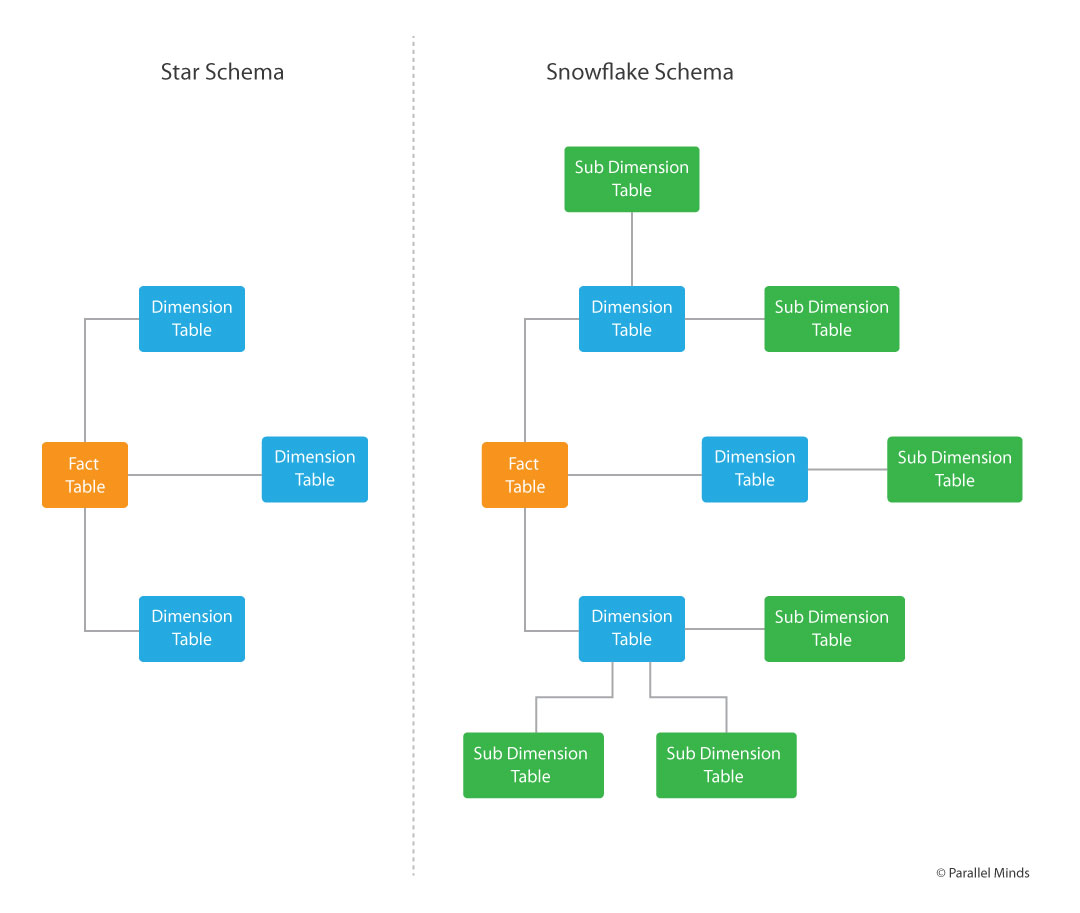

You will find the answer to these questions, and the solutions to your many software development problems, in Value Stream Mapping (VSM). A concept borrowed from Lean manufacturing, this visual tool is capable of mapping out entire workflows of work and information to direct every process component from the initial request to final delivery. At every stage, VSM red flags hidden waste and inefficient steps to help you plug time and resource drain.

Set it up optimally and VSM is a lot more than just a diagnostic tool. VSM can act as the bridge between your current state and planned future state by helping you zero in on targeted improvements and line up tech solutions to overhaul your operations through lean, efficient, and resourceful improvements.

Identifying Common Pain Points in Tech and Acknowledging Impact

Identifying these pain points and acknowledging the operational inefficiency they introduce at various stages is a crucial first step in setting into motion the plan to streamline your processes.

Excessive Handoffs: Projects changing hands too often with numerous teams and individuals involved. This leads to a breakdown in communication and complicates collaboration and decision-making.

Waiting Time: Idle gaps in the process while waiting for resource approvals or resolutions can add days and weeks to project timelines, demotivating teams and stalling progress. These gaps also lead to attrition.

Overprocessing: Redundant systems depending on manual inputs add unnecessary steps to the process, increasing complexities, adding to errors, and weighing down the entire development cycle.

Defects and Rework: When error rates are high, they translate to increased reworks and bug fixes, resulting in a drain on resources, repetition of efforts, and ultimately, unsatisfied clients and lost reputation.

Lack of Visibility: In the absence of real-time visibility and transparency, teams are only putting out fires when they should be proactively introducing efficiencies. This general chaos hinders communication and leaves customers stranded with little or no information.

Tech Issues: The lack of automation and outdated tools and platforms force manual intervention, which in addition to wasting human hours, further adds to errors and delays as well as exhaustion and frustration.

The Current State Map: Your Present Reality Snapshot

The Current State Map is a visualization of your current workflow state. With the help of key components, it presents you a picture of not how you THINK your workflow functions but how it TRULY functions.

Process Steps: Break down steps, identify individuals, teams, or systems responsible for them, and line up the entire process from request to delivery.

Information Flow: Trace data and request paths, identify system and manual collaborations, and tag every information-exchange touchpoint.

Time Data: Track the duration of each step, calculate wait times, and decipher just how much lead time it takes from start to finish.

Inventory or Work in Progress: Identify bottlenecks, ticket queues, features stuck in development, and every possible juncture where things get stagnant.

Key Metrics: Measure, calculate, and apply quantifiable metrics to each element. Whether it is escalations or revisions, put a number to everything.

This current state map reveals shortfalls, inefficiencies, and wastes, only so you can identify the pitfalls of your current workflow and identify and prioritize areas of improvements. In opening your eyes to these shortcomings, you can now envision a seamless workflow and optimal operations and leverage tech advancements to accomplish these goals.

The Future State Map: Your Blueprint for Streamlined Tech Operations

Create and use your Future State Map as a visualization of the state of processes you would like to achieve. Dedicate this blueprint to making your operations leaner, quicker, efficient, and tech-enabled. Key focus areas in your Future State Map must include:

Waste Elimination: Identify and eliminate all steps in your process that add no value, streamline handoffs,reduce wait times, remove bottlenecks, and optimize resource mileage.

Optimized Workflows: Identify gaps and streamline workflows, work towards a pull system, and aim to work on and reduce work-in-progress projects to add value and flow to operations.

Tech-Enabled Processes: Line up specific tools and platforms to address pain points discovered in the Current State Map. Aim to eliminate manual tasks, introduce analytics dashboards, and break down silos.

Measurable Goals: Assign quantifiable terms to tasks and targets, set specific and measurable goals, and use metrics to guide your objectives onto the right track and eventual fruition.

Collaborative Platforms: Set up collaborative platforms to assess and assign responsibilities, increase communication between teams and individuals, and add transparency to your operations.

The Future State Map can never be expected to accomplish an overnight transformation, but it surely guides your efforts and assigns to it a clear and defined blueprint so that you may prioritize your efforts and investments on the way to achieving process optimization on all fronts.

Digital Tools as Your VSM Allies for Lean Optimization

Armed with your Current and Future State Maps, you can now achieve your Value Stream Mapping (VSM) goals by strategic tech adoption. Here’s how you can define your tech stack to achieve your VSM goals by strategically introducing the right technologies into specific value streams and achieve the optimized vision in your Future State Map.

Automation and Orchestration: Introduce automation tools to automatically trigger actions based on the completion of tasks. This eliminates delays caused by wait times for approvals. Orchestration platforms help visualize dependencies and eliminate bottlenecks while allocating resources and automating approvals. In software development, CI/CD (Continuous Integration/Continuous Deployment) pipelines accelerate development and deployment.

Real-Time Data and Analytics: Your VSM provides real-time information provided by integrated systems through data dashboards. Tracking KPIs helps identify bottlenecks, and advanced analytics helps forecast problems and line up appropriate proactive action. In IT service delivery, for example, real-time analytics helps streamline processes by identifying hidden issues.

Collaboration and Communication Platforms: Slack, MS Teams, and other similar tools act as a central platform for communication, information-sharing, and even documentation, reducing the risk of lost information. Real-time updates and prompt feedback and troubleshooting lead to a connected and united work environment. Even in distributed work environments, these cloud-based tools help overcome the challenges of location and provide a highly collaborative work platform.

Cloud Solutions: The scalability of cloud solutions make them resourceful and affordable, and give your infrastructure the flexibility it needs to work optimally in a global environment. AI and machine learning tools make the cloud even more conducive for tasks that require scalability without compromising on tool and platform access.

Tailored Tool Recommendations: CI/CD platforms, service desk software, data warehousing and business intelligence tools, and process mining tools add up to a formidable lineup that optimize functions to accelerate software delivery. Whether it is consolidation of data from multiple sources or uncovering deviations and setbacks, these tools address specific issues and offer integrated solutions that work in tandem with the system.

While defining the tech stack can also be an ongoing process, optimizing this lineup requires the strategic integration of tools and platforms so that the future state you’re aiming for can be achieved with minimal waste of time and resources.

Parallel Minds: Helping You Adapt to the Iterative Nature of Improvement

At Parallel Minds, we fully grasp the iterative nature of improvement and understand the need to revisit maps as your business and the tech around it evolves. Our list of optimizations take into account the size and nature of your business and our customized VSM solutions bridge the gap between business ambitions as well as operational potential and achievable states.

Get in touch today and our team will help your business map its way to a leaner and more successful state.

Share:

More Posts

Value Stream Mapping – Current and Future States

If you’ve ever witnessed a brilliant idea with the potential to develop into a successful

The Digital Evolution of a Lean Manufacturing Ecosystem: The Turnaround from Waste to Profit

As leaders in the tech space, we owe it to our respective industries to revolutionize